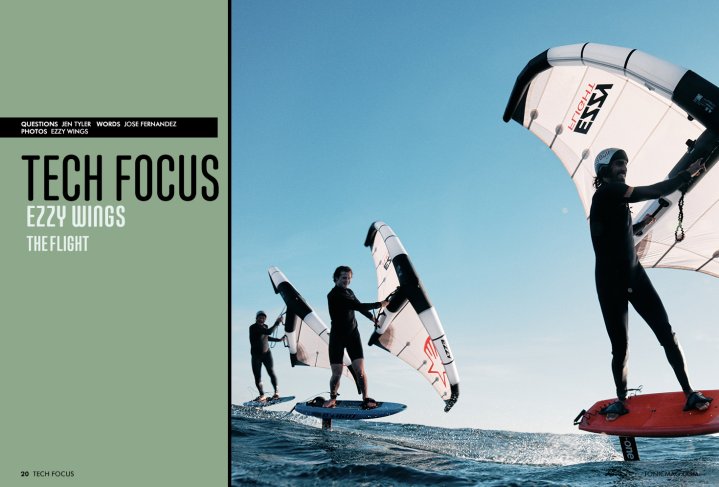

Tech Focus - Ezzy Wings

Issue 20 / Sun 19th May, 2024

The Ezzy Flight Wing is a collaboration between Jose Fernandez and David Ezzy. They have a combined 75 years of experience and have created wings in Sri Lanka. The high-performing wing first came on the market in March 2024, and we couldn’t wait to find out more about it! Dive into The Flight’s Tech Focus here!

It's great to meet you, Jose! Please tell us a little bit about Ezzy Wing's background.

The Ezzy Flight Wing is the result of a partnership between Jose Fernandez, the owner and designer of Flight Sails, and David Ezzy, the founder and owner of Ezzy Sails. With a combined experience of 75 years, they have come together to create wings crafted with precision and care in their own factory in Sri Lanka. Their commitment to excellence, design, and performance is reflected in each wing they produce.

When did The Flight come on to the market? Can you tell us more about the wing?

Our work on developing wings began in 2019, and the Ezzy Flight was introduced in March 2024. We strive to create user-friendly, long-lasting, high-performing, and affordable wings.

Your website mentions the importance of high skin tension. Why is this important?

High skin tension is crucial for a wing's stability and performance since it minimises deformation under load. In other words, high skin tension ensures the wing's profile is aerodynamic rather than droopy.

What materials are used in the handles of The Flight wing, and how do they contribute to comfort during use?

We use marine grade 6061 aluminium covered with 2mm EVA foam.

The leading-edge handle is curved and raised in the front for comfort and faster launches. The rear handle is straight to give your arms a perfect ergonomic fit while flying.

Could you provide more details about the low-stretch Dacron used in The Flight wing's leading edge and strut?

We use 160g of Dacron fill-oriented fabric made by Challenge Sailcloth for the leading edge and strut. The low-stretch properties provide exceptional durability and structural integrity even under the most demanding conditions.

What are the benefits of having separate leading edge and strut valves in terms of adjustability and safety for the rider?

There are two advantages: 1. You can still make it in if the strut bladder fails, and 2. deflation is faster with two valves.

Could you share the testing process that The Flight wing undergoes to ensure its top-notch quality and performance?

We have two testing centres, one in Maui and the other in Tenerife. Additionally, our factory enables us to quickly create and test prototypes, a continuous process that helps us improve our wings. We value feedback from riders of all skill levels.

Are there any exciting plans for 2025 you’d like to share with us?

We believe in making small incremental changes to our prototypes, just like we do with our sails, hoping they will lead to significant improvements. For 2025, we focus on three main goals: refining our designs, researching and testing potential lightweight and durable materials with low stretch, and improving our manufacturing precision.

We are excited about what awaits us in 2025 and hope our work will inspire people to use our wings!

Thank you so much, Jose! This sounds very exciting!

Thanks, Jen!

Videos

By Jen Tyler

Italian/Egyptian Jen Tyler grew up on the sandy beaches of the Red Sea and has been on the IKSURFMAG & Tonic Mag team since 2017.