Tech Focus - Armstrong Foils Alloy System

Issue 20 / Sun 19th May, 2024

Are you looking to explore the world of Armstrong Foils Alloy System? You're in luck! Our latest Tech Focus feature has all the information you need to know. Get ready to immerse yourself in the exciting world of Armstrong Foils Alloy System!

Armstrong goes alloy… Most brands started with aluminium and moved to carbon, but you’ve always been famous for only using carbon for your foils; what was the reason for adding aluminium to the range?

We are big fans of carbon fibre and titanium in our masts and fuselages. As you mentioned, from the very start of Armstrong, these components have been carbon and titanium. That said, aluminium alloy offers some exciting opportunities, mainly because it’s a terrific way to get more people into the sport of foiling. Price accessibility is no small thing. And alloy presented our team with an exciting opportunity to apply the Armstrong ethos of high-quality design and manufacturing to a new material to improve how fun an alloy foil could be.

Carbon is often seen as stiffer and lighter, but aluminium is a pretty incredible material, too; how close are they in terms of weight and performance?

Historically, marketing has told us that “carbon is good, alloy not so good,” but the degree of difference depends on the variety of each material used and the layups. Without generalising, a high-quality alloy mast may be stiffer and lighter than a so-so carbon mast. Conversely, a top-tier carbon mast will likely outshine the best alloy mast in weight and stiffness. It’s a design and construction story and partly how the foil gets ridden.

In an alloy mast, the grade and placement of that alloy—basically the ingredients in the sauce and where they’re used—greatly affect the design itself. The Alloy System mast vertical is crafted from 6061 aluminium alloy because it has the ideal strength-to-weight ratio. Meanwhile, the mast top, bottom bracket, and fuselage are 7075 aluminium alloys for maximum strength in those areas where loads are mainly concentrated.

Section shape and thickness, chord, taper, and many other factors contribute massively to how a mast or fuselage (regardless of material) ultimately feels on the water. Those determine responsiveness, top speed, stability, recovery from ventilation, etc. Every mast will have a different combination of those features and characteristics, and one might matter more to you than another if you’re prone to surf foiling versus cruising on a wing.

The long and the short of it is: if you decide between alloy and carbon, you’ll probably be super stoked on alloy for a lot of the riding you’ll do. Sure, our carbon masts have a faster top end, are zippier and have that signature smooth Armstrong feel that is so loved, but any of us on the team would gladly rip our favourite foil on an Alloy System setup any day.

You had to develop a new foil connection system to facilitate the new material in the line. How long was that process, and was it challenging to develop something that worked well and was future-proof?

The mast-to-fuselage connection point is new, but the front foil and stabiliser connections fit precisely the same hexagonal design as our existing carbon A+ System. This means all our front foils and stabilisers fit, regardless of whether you choose the alloy or carbon mast route (or both).

We were not in a rush to develop the new design; it’s a critical connection to get right. As with our Performance Series products, we recruited our design consultants from SailGP to help with the machined bottom bracket. It’s a press fit, which means when you tighten down the screws, the whole system snugs up and fills the space with a high tolerance and clean fit. It’s a neat component if you can hold one in your hand.

Along with that bottom bracket, we ended up making our custom titanium M7 and M8 x 1.25 screws for the mast to the fuselage connection point. That M7 was necessary to fit the skinny space available at the trailing half of the mast section while achieving the optimal placement for structural needs. Those are some beautiful screws that we’re stoked about.

While we don’t claim to control the future...aiming to get the design sorted the first time around certainly can reduce the need to refresh the core elements of a product later on. It allows riders to invest in a system, knowing it’ll remain relevant for a long time. We like that.

You’ve tried keeping the front wing connection similar to the carbon setup. Was it intentional to keep as much Armstrong DNA in there as possible?

The commonality is a core design tenet at Armstrong. If you build out a quiver of front foils and stabilisers while on the Alloy System and one day decide to switch to one of our carbon masts (or vice versa), everything fits from the word go—no adapters, no worries.

What are the cost savings for the consumer on average?

When considering a mast, fuselage, and hardware together and generally comparable component sizes, Alloy is about half the price of Carbon and roughly a third the price of Performance Carbon.

There are currently only three mast sizes; will that change in the future to offer more options?

Currently, the Alloy System has 85, 72 and 58cm masts and 75 and 65cm fuselages. That covers most riders' needs, from beginner to advanced, in different foil sports, from winging to surfing and wake, so we’re happy with that lineup.

Where does the Alloy System sit in the range for foilers?

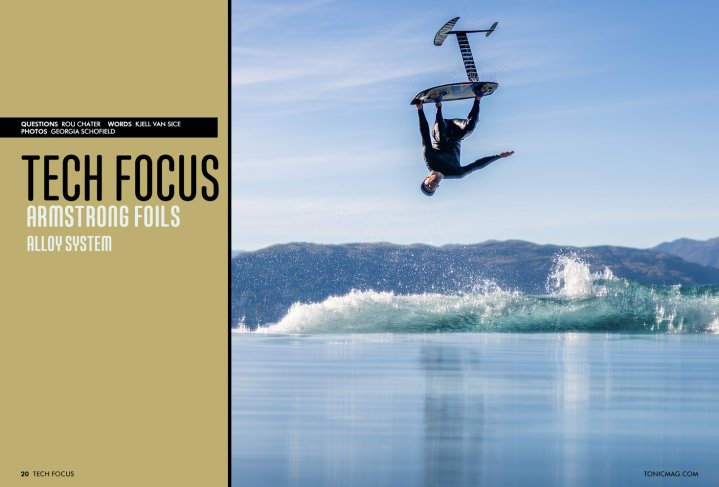

It covers everyone, whether you’re advanced or just starting. The top-end speed of the Alloy mast caters perfectly to most riders in most foil sports. It’s strong enough to take the impact of full send jumps but still light and comfortable enough to be your daily driver.

Because of the titanium and stainless steel hardware, you can leave the major components together between sessions with minimal risk of corrosion. That translates to a setup that’s easier to take care of when you’re learning and then something that will take you through your more advanced days. Regardless of where you’re in your foiling journey, the Alloy System's quality, durability and performance make it an excellent investment when looking down the road at your progression. If you’re looking for the smoothest, zippiest and most premium ride feel, our carbon A+ System does that well. Either way, we think you can’t go wrong.

When will it be available in stores?

Right now! Reach out to your local Armstrong retailer.

Videos

By Rou Chater

Rou Chater has been kitesurfing for over twenty years, paddleboarding for the last six years, and was there testing the first wingsurfer from Naish in Tarifa when it arrived on the continent. He is passionate about riding waves and exploring new places. As the publishing editor, he oversees everything at Tonic but also our sister magazines IKSURFMAG and IMB. He's been on the water since he was born and has never looked back, in the winter you'll find him chasing swells in the Caribbean and during the summer he can be found all over Europe at various SUP, Kitesurf and Mountain Bike events getting features for the magazines.