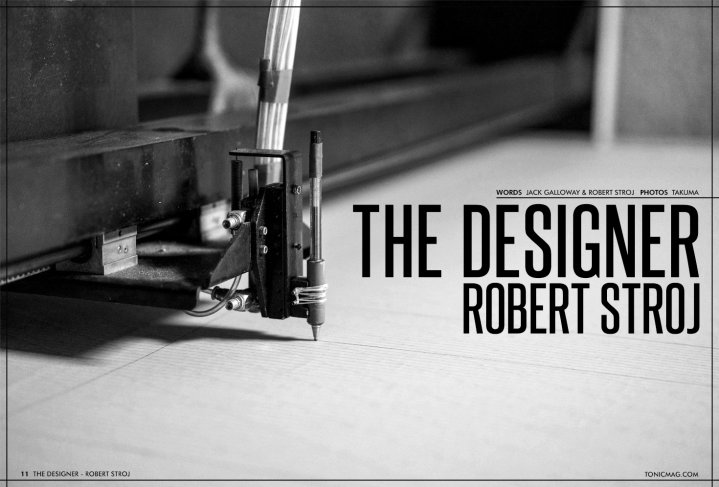

The Designer - Robert Stroj

Issue 11 / Fri 18th Feb, 2022

Takuma has a brand new wing incoming; the RS. Jack Galloway sits down with designer Robert Stroj to find out what we can expect from this exciting new edition to the Takuma line up.

Takuma has a brand new wing incoming; the RS. Jack Galloway sits down with designer Robert Stroj to find out what we can expect from this exciting new edition to the Takuma line up.

Hi Robert, thanks so much for joining us. Could you start by telling us a little about yourself and your extensive career in the sail design industry?

After studying naval architecture I learned sail making and got into windsurfing sail design at Monty Spindler sail loft on Garda, which was around 1990.

From Garda, I moved to Tarifa and was working there for Fanatic / Art till 2000, when I got hired by Neilpryde and moved to Maui.

With Neilpryde I had the opportunity to work with very top sailors in all disciplines, gaining world titles as well as overall speed sailing records with Antoine Albeau.

What led you to decide to move to Takuma?

There were two main reasons;

I really liked the product range at Takuma including the E-foil products as well as really exciting products that were in development.

Also, the team at Takuma was very nice while professional, super enthusiastic and the whole energy in the company was really good!

What was the task at the very beginning for this new wing?

Cyril gave me a pretty open brief, but the idea was to design an overall performing wing that would work well on flatwater freeriding as well as flying balanced off the front handle and be good in waves or downwind runs.

The exciting part here was that it was not going to be a budget wing where the production price would be the important factor; instead, we were free to innovate and use the best materials we felt were suited for the purpose.

Is this an updated version of the WR Wing or is it a completely new design?

This design is totally new and has no connection to WR designs.

Other than focusing on the actual outline, profile, and materials. I really wanted to combine the ergonomic advantages of the boom with the lightweight advantage of webbing handles.

In addition, I felt there was a big benefit from being able to extend the distance between the rider and the wing in the front relative to the back hand position.

Out of those ideas our lightweight carbon “Direct Control Bars” developed; they weigh the same or less than some of the “batten-reinforced flat webbing handles” but provide a super comfortable small diameter oval grip and very precise, direct connection with the wing.

Also, the fact that they are ergonomically designed to “hook” to your fingers and not twist in the arm there is much less effort required to hold on during long sessions.

Compact elliptic outline of RS wing results in a significant overall reduction of LE and canter strut lengths which reduces the weight of both, Dacron material as well as internal bladders.

To keep the outline shape stable even in strong gusts we incorporated “Power Tip Battens”; these are flat battens located at the compression-side of the tips which resist compression, prevent buckling of the inflatable tips and result in much higher tip stiffness for the same diameter.

The big challenge with using the lightweight woven materials in the sail is preventing the stretch and deformation from the loads.

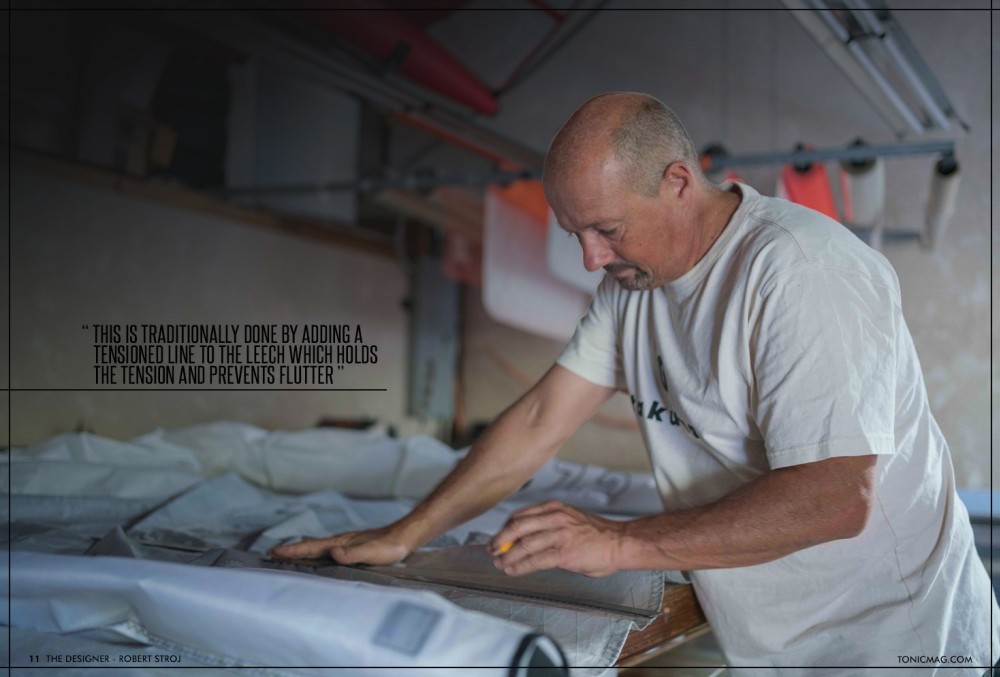

This is traditionally done by adding a tensioned line to the leech which holds the tension and prevents flutter; the problem of this approach is that the profile is compromised resulting in excessive back-hand pressure when loaded as canter of effort moves back.

We chose to keep the efficient profile with a flat rear section and integrate Aramid reinforced X-ply laminate in the high load leech area.

This together with super-light flat composite leech battens controls deformations in this area and provides a stable profile shape even after many sessions.

Are you able to talk us through your design process?

It starts with a 3D model which is designed with profiles and twists that would work as an optimal compromise between low-end power, stability in gusts, and stable flight when depowered.

This model then gets adjusted with lots of factors that influence the final shape, mainly the stretch and deformation of inflatable components.

Once all the adjustments are made the panels get “unrolled” and transferred into 2D flat shapes that are then plotted and cut into the panels.

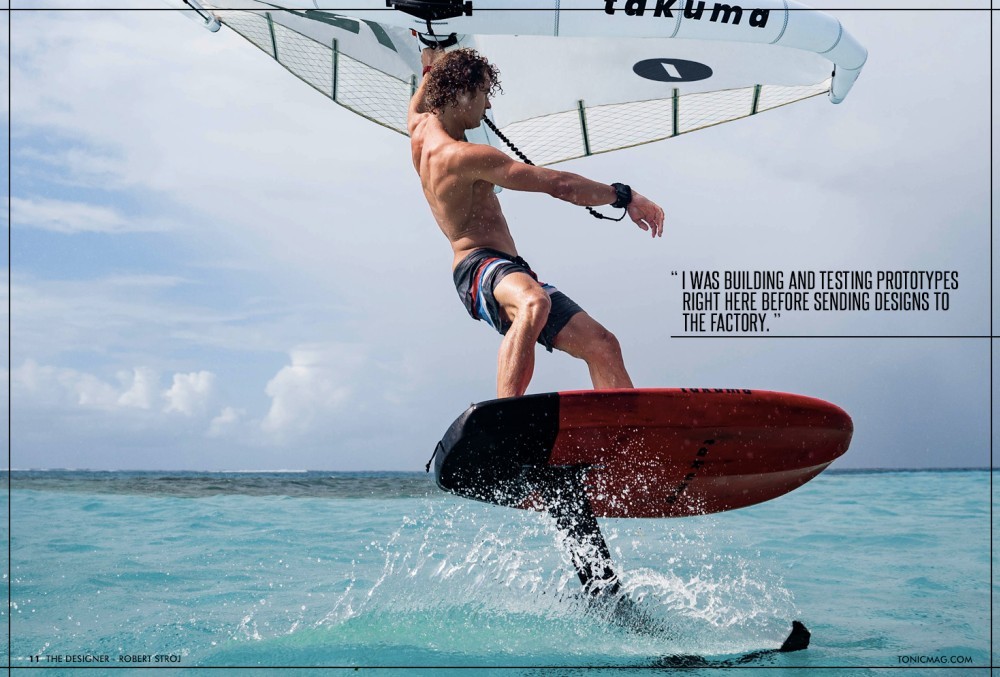

What is different now with Takuma to the majority of other brands is that we got a fully equipped prototyping sail loft here on Maui so I was building and testing prototypes right here before sending designs to the factory.

We are using a computer-controlled plotter/cutter table to cut the panels in exactly the same way they are made at the factory and then we stick and stitch the wings together for testing here on Maui.

This not only speeds up the process but also lets me learn hands-on about different construction techniques and improve on details right between each of the prototypes made as well as being able to make changes and re-cuts on existing prototypes and then re-test the following day.

Sounds super effective! What has the feedback been like from the team?

So far very good. The main points I keep hearing are a direct response from the carbon handles, a very wide wind range, and a super-light feel when flying.

What’s the size range?

The sizes are 2.8, 3.5, 4.3, 5.1, 6.1, and 7.2;

Thanks Robert, we can’t wait to get our hands on one to test!

By Jack Galloway