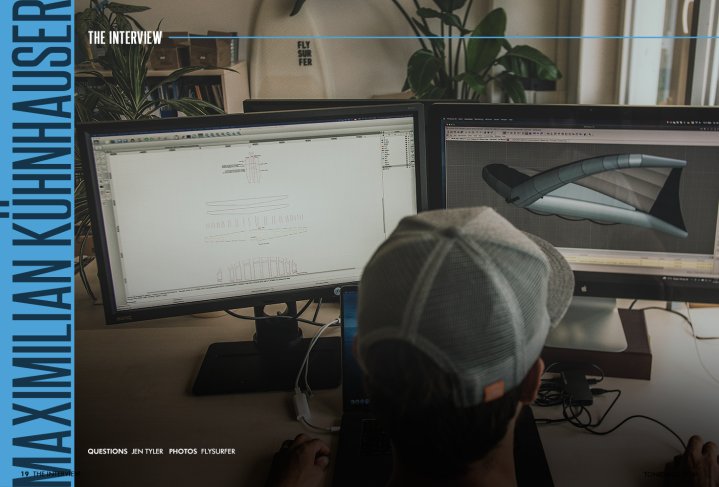

The Interview - Maximilian Kühnhauser

Issue 19 / Mon 26th Feb, 2024

Dive into the dynamic wing and kite design world with our exciting interview with Maximilian Kühnhauser. Explore Maxi's journey as he shares his innovation-driven approach to product development. Get a glimpse of the upcoming releases from FLYSURFER and join us in anticipating the exciting future of wingfoiling!

Hi, Maximilian; it’s a pleasure to meet you! Tell us a little about yourself, where you grew up, and how you first got into watersports.

Hi Jen! It’s a pleasure to meet you as well. I spent my childhood in the southeastern part of Bavaria, Germany, surrounded by the Alps. In 2005, my fascination with watersports began when I first started kitesurfing on Lake Lago di Resia in Italy.

When did you start wingfoiling, and what attracted you to it? Did you immediately fall in love with the sport, or did it take a while?

I took up wingfoiling at the beginning of 2020 at our home lake, Chiemsee. At first, I was hesitant about this new sport, but I soon realised how accessible it was. Our lake is surrounded by trees, making it difficult to find a convenient spot to enter the water. But I could launch from any location with the wing foil setup. Also, Lake Chiemsee is known for its gusty winds caused by the nearby mountains. Thankfully, this wasn't a problem anymore. My initial attempts at wingfoiling were in winds ranging from 8-11 knots, which was hard work to stay on the foil. But once I experienced perfect wind conditions during one session, I was hooked and knew we had to develop a special wing - the MOJO.

When did you first get into kite and wing design?

I began my career as a designer in February 2016. It was an exciting experience when I started with a trainer kite. I started with the STOKE, a new LEI Kite model, in the same year. In 2020, I ventured into wing design, which felt like pioneering work and was really cool.

Can you explain the key principles behind wingfoil and kite design?

Don't overcomplicate things! Be innovative from the start of a project. Make sure the product is 100% tested before mass production.

How much time typically goes into your design process, from the initial concept to the final product?

The design process can be split into several different phases. This includes working on the files using computers, conducting tests, providing instructions for serial production, and preparing data and media. It is challenging to provide an exact time estimate for the design process as it heavily relies on the nature of the project. Factors such as whether it is a new project with no previous groundwork or if there is already an existing base and the project's complexity play a crucial role. When you develop more high-performance products, you usually need more time.

Can you tell us about a design you are most proud of and why?

I feel super proud of the TAO wing as it is remarkably lightweight without relying on excessively costly materials, maintaining an affordable price point. Its exceptional performance, extensive wind range, and outstanding stability make it a fantastic package. For this reason, I am incredibly proud of the ERA LEI Kite. Not only is it our inaugural Big Air kite, but it has already established itself as a fiercely competitive model, consistently achieving top scores in the WOO ranking.

Have you ever faced a significant design challenge, and how did you overcome it?

Every project presents its challenges, which is good and makes the job interesting. One particular design challenge was creating a new Quick Release. Meeting all the requirements to ensure a safe, functional, and long-lasting QR was hard. Successfully overcoming such intricate design challenges demands focus and belief in one's abilities. Knowing how to handle difficult periods in difficult times helps when you do the job for a few years.

How did you get started in this industry, and what experiences have shaped your career?

My initial education was in carpentry, where I learned a solid foundation and practical understanding. I made my skis, snowboards, and longboards during this time, similar to kiteboards. Learning how to prepare materials properly, utilise the right tools, and establish efficient workflows proved invaluable for optimising our production process. After my carpentry education, I got a Master's in Sports Equipment Technology. This program gave me the comprehensive knowledge and skills to design cutting-edge sports equipment. In parallel to my studies, I worked as a kitesurfing and snowkite instructor, allowing me to gain valuable experience and insight into the world of kiteboarding; combining my academic background with hands-on experience as an instructor set a strong foundation for me to pursue a career as a kite designer. With existing connections at Flysurfer, I always wanted to be part of this company. Luckily, I got part of the company quickly, and after two years of working as a workshop leader, the former LEI kite designer left, and I got the company's trust.

Oh wow, and when did you first join the FLYSURFER team?

I joined the FLYSURFER team in 2013

Besides kite, wing and bar design, rumour has it that you enjoy woodwork and have done quite a bit of work on your home. Do you use any unconventional materials to work with?

That's true! I love crafting my own pieces, especially for my own home. I only use organic materials like wood, natural stone, metal, and ceramics. I believe utilising genuine natural materials and creating everything to last a lifetime is incredibly sustainable. It takes a lot of time to do this, but at the same time, it’s so much fun seeing the result at the end and teaching your own kid how everything is working.

Please tell us a little about your trip to South Africa. Are there any exciting products in the pipeline we should watch for?

Over the past two years, we have been testing our equipment primarily in Cape Town, which has proven to be the perfect base for us, thanks to the presence of Luke McGillewie, an exceptional rider and a valuable collaborator in our LEI kite designs. With Luke as a local and the nice wind conditions, Cape Town is just the perfect spot to test the equipment in all conditions in the best way. When the stuff survives in Cape Town, you know it’s ready for the market.

Some exciting developments are happening at Flysurfer right now. I am thrilled to reveal that we will launch a Wing with durable handles, an innovative one-strut LEI Kite, several new bars, and an array of follow-up products.

Can you discuss the process of prototyping and testing in your design work?

At the start of the project, we held a kickoff meeting with the R&D team, the head of Flysurfer, and the product manager. We determined our objective and set a timeline. After this step, we engage in extensive prototyping, which involves designing files on the computer, testing prototypes, and analysing each one. This cycle is repeated until we approach the production start date when we must finalise the product. After the product development cycle, coordination becomes crucial. This entails creating manufacturing instructions, overseeing production, providing all files and technical data for marketing visualisation, ensuring timely delivery of finished products for video shooting, and conducting demonstrations and training sessions with sales representatives and internal staff. Finally, we celebrate the product launch with an exciting in-house launch party!

How do you see wingfoiling evolving in the next few years?

In my opinion, wingfoiling is set to experience exponential growth in terms of participation. I see big problems stemming from discounters and excessive manufacturing. Making products of good quality for long-term use and at an affordable price is something that will become more and more important. Flysurfer's commitment to crafting products of exceptional quality over two years aligns perfectly with my ethos. The upcoming improvements in wing efficiency hold great promise and have me eagerly anticipating what lies ahead.

If you could give one piece of advice to aspiring wingfoil and kite designers, what would it be?

Stay consistently super passionate and dedicated to what you want to do! It's not solely dependent on your education or background but your motivation and focus.

Thanks for your time, Maxi!

Thanks a lot for inviting me to this interview. It was a pleasure!

Videos

By Jen Tyler

Italian/Egyptian Jen Tyler grew up on the sandy beaches of the Red Sea and has been on the IKSURFMAG & Tonic Mag team since 2017.